Delkia and Omniflex collaborate on a Radiometric Surveillance System to SIL-2 criteria.

Cumbria-based specialist systems integrator Delkia has developed a radiometric surveillance system (RSS) in partnership with alarm equipment manufacturer Omniflex. The collaboration comes at a time when nuclear industry customers face increasing scrutiny of their adherence to ALARP principles, and therefore need a reliable, low-cost remote monitoring system to protect their assets and workforce from unintentional radiation exposure.

Nuclear sites must adhere to strict ALARP regulations on the use of field instrumentation for hazardous detection of alpha, beta, gamma and neutron radiation in the environment. However, current systems can’t relay real-time information from these instruments to the control room and developing hazards may go undetected. Even if hazards are detected, operators must risk the exposure to avoidable dosage uptakes to fix the problem.

To tackle this, specialist systems integrator Delkia has been developing equipment for radiometric surveillance, including associated protection and evacuation systems up to SIL-2 criteria.

“Remotely monitoring radiation in a facility brings about huge benefits for employers in the nuclear industry. The problem is, current systems are only pulling out very basic information,” explains Mark Sisson, nuclear relationship manager at Fit For Nuclear accredited company Delkia. “For example, if gamma radiation is detected above a certain threshold, an alarm will sound to trigger an evacuation. Crucially, you have no diagnostic capability. Rectifying the issue might also involve exposing someone to the radiation to diagnose the problem, bringing into question the nonadherence to ALARP principles.

“Using Omniflex’s Teleterm M3E hardware, we’ve developed an RSS solution that allows for trend analysis and data monitoring in real-time. The system can both initiate an evacuation and lock down the client’s facility by using audible and visual warning units that are individually rated to SIL-2 level. This is all at an affordable cost, which has removed a common barrier to small scale RSS implementation,” continues Sisson.

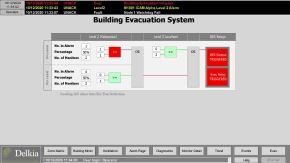

Delkia has programmed the remote terminal units to take multiple inputs from activity-in-air and gamma dose rate monitors and bring them into a single consolidated HMI display. Through this, the operators can also carry out predictive maintenance and operational control remotely. Where required, Functional Safety Envelopes can be designed up to SIL-2, depending on the hazard detection equipment utilised and the protection measure to be deployed.

Because Stockport-based Omniflex has honed its telemetry technology over 55 years working in safety-critical industries, it is well-versed in the requirements needed for low cost, flexible and ultra-reliable equipment modules.

“We’ve collaborated with Delkia for many years now. So, when they approached us for robust and reliable data collection and logic control hardware for their RSS, we were more than happy to come aboard,” explains Gary Bradshaw, director at Omniflex UK. “The HMI display outlines a floorplan of the facility. If an abnormal reading is reported from one of the monitors, personnel can be notified immediately via SMS or email so that action can be taken promptly.

“These collaborations combine our experience in software development and systems integration with Omniflex’s extensive knowledge of interfacing to all types of radiation monitors and technical support,” adds Sisson. “In an industry where safety is paramount, partnerships like these create the technology that ultimately protect assets, people and the environment from preventable radiation exposure. Long may it continue.”

Downloads

File size: 57.801 KB

News by Category

- BECBC

- Cumbria

- Nuclear

- Social Value

- Professional Services

- Clean Energy

- Business

- People

- Government

- BECBC Member News